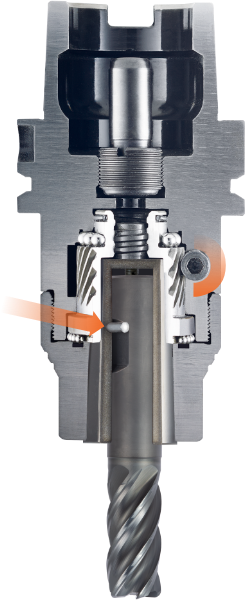

New EMUGE high precision/performance FPC Mill/Drill Chucks provide unprecedented rigidity, vibration dampening, concentricity, machining speed, and tool life vs. conventional chuck technologies for milling and drilling applications. Available in a wide range of styles. Internal and peripheral coolant options, and MQL-adaptable.

Reliability

Extremely high transferable torque provides maximum process reliability.

More accurate

With a 3XD tool length, concentricity is ≤ 3 µm, guaranteeing long tool life and quality surface finishes.

Longer tool life

Special holder design reduces vibration, dramatically improving work piece surface finishes and providing exceptionally long tool life.

Fast tool change

Simple, highly accurate design enables quick tool change in seconds, via hex wrench.

Perhaps you’re on the fence over shrink fit vs. hydraulic toolholders. Or maybe your shop still uses Weldon side-lock holders and wonders why tool life is less than spectacular, or struggles with pull-out no matter how hard you tighten that collet chuck. You’re not alone. Many shops are using the same toolholder technology they started out with decades ago and are reluctant to invest in something new, or are confused over which direction they should go.

We've shared a few pro tips on assembling and disassembling our high precision/performance FPC Mill/Drill Chucks.

Here's a quick tutorial video showcasing collet assembly and torqueing options.

The FPC tool holding program includes the following options.

Let our experts provide recommendations for your project or application.

EMUGE-FRANKEN USA is a wholly owned subsidiary of the 1,500+ employee German company EMUGE-Werk Richard Glimpel GmbH & Co. KG (Lauf, Germany). A product technology and performance leader for over 100 years, EMUGE-FRANKEN manufactures an extensive line of taps, thread mills, drills, end mills, toolholders, clamping devices, and other rotary cutting tools.

EMUGE-FRANKEN also offers end-user technical support through a network of in-the-field engineers and in-house product specialists, all with extensive tooling and application experience.

Additional services include tool and tool holder repair and reconditioning, test cut services and CNC programming assistance.